Custom Ultrasonic Bag Manufacturer & Supplier in China

Ultrasonic bags are made using high-frequency sound waves to bond fabric without stitching or glue. This creates smooth, clean seams with no loose threads, making the bags stronger and more eco-friendly. Ideal for packaging, promotions, and retail, these bags are lightweight, durable, and fully customizable in size, color, and logo.

Varied Ultrasonic Bag for Every Need

Explore our range of ultrasonic bags designed for retail, gifting, and daily use. Each style offers seamless strength, clean edges, and full customization to match your brand.

Non Woven Ultrasonic Bag

Lightweight, durable non-woven bags made with ultrasonic welding for strong seams and eco-friendly reusable solutions.

Ultrasonic Tote Bag

Seamless ultrasonic tote bags offer a sleek, modern look with reinforced strength, perfect for retail, events, promotions, and daily use.

Ultrasonic Welded Bag

High-quality bags crafted with advanced ultrasonic welding technology ensure clean edges, no stitching, waterproof seams, and lasting durability.

Ultrasonic Shopping Bag

Eco-friendly, reusable ultrasonic shopping bags combine style and strength with seamless construction for everyday convenience.

Your Professional Ultrasonic Bag Manufacturer in China

With years of manufacturing experience, we offer a wide range of custom ultrasonic non-woven bags designed for retail, packaging, and promotional use. Our bags are produced using advanced ultrasonic welding technology—ensuring smooth seams without thread or glue. This results in a clean, strong, and eco-conscious alternative to traditional sewn bags. From tote bags to drawstring styles, every design can be fully customized in size, shape, color, and logo to match your brand. Whether you need high-volume orders or tailored solutions, we provide fast turnaround, competitive pricing, and reliable global shipping. Partner with us to elevate your packaging with precision and professionalism.

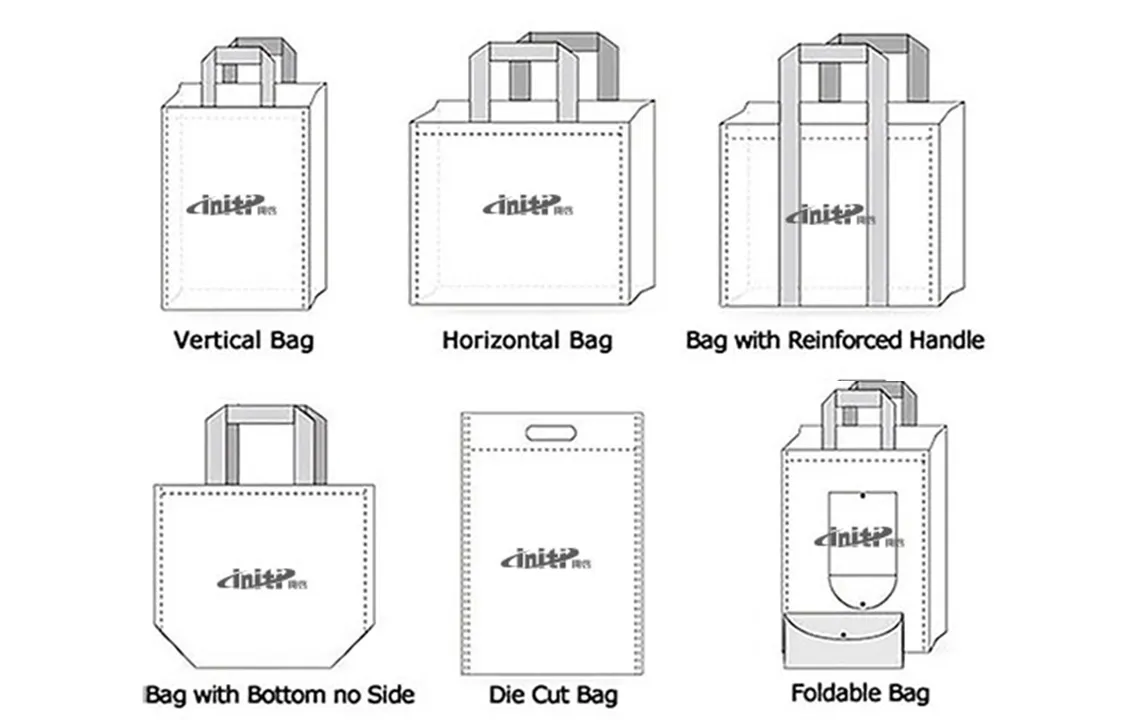

Product Types We Offer

We create a wide range of ultrasonic bags to suit different needs. From soft drawstring pouches to structured tote bags, every style is designed with strong, seamless bonding for a clean finish. Choose from flat bags, handle bags, gift bags, or custom shapes—we tailor each piece based on your purpose.

Versatile Size

We provide a variety of customizable sizes to suit your specific needs. From small pouches (around 10×15 cm) for compact items to medium bags (25×30 cm) for everyday use, and large totes (35×45 cm or bigger) for bulky products. You can specify exact dimensions, and we will craft bags tailored perfectly to your requirements.

Materials We Use

Our ultrasonic bags are primarily made from eco-friendly non-woven polypropylene (PP) fabric, known for its:

Lightweight structure

Water resistance

Breathability

Recyclability

We also offer:

Laminated non-woven fabric for added strength and a glossy/matte finish

Embossed or patterned surfaces for visual appeal

Custom thickness options (from 60gsm to 120gsm and more) depending on usage

All materials are certified safe and compliant with global packaging standards.

What Is an Ultrasonic Bag?

An ultrasonic bag is made by bonding fabric together using high-frequency ultrasonic vibrations—no sewing, no thread. We use ultrasonic welding technology to fuse the materials directly, which makes the seams clean, strong, and uniform. These bags are especially great when you want a clean finish without needle holes or stitching lines.

At our factory, we typically produce ultrasonic bags using non-woven fabric, PP, PET, or other eco-friendly materials. The whole process is quick, precise, and consistent, which helps reduce labor costs while improving efficiency and appearance.

If you need a bag for promotions, shopping, or lightweight packaging that looks neat and lasts long, ultrasonic bags are a smart choice. Plus, we can fully customize the size, handle type, printing, and color to match your branding.

What are the advantages of ultrasonic non-woven bags over stitched ones?

Ultrasonic bags offer cleaner edges, stronger bonding, and no thread breakage. They are more durable, hygienic, and better suited for high-volume automated production.

Can I customize the size and design?

Yes, all ultrasonic bags can be fully customized in terms of size, color, handle type, thickness, and printed logo.

Are these bags eco-friendly?

Yes. Our bags are made from recyclable polypropylene fabric, and we also offer biodegradable and laminated options upon request.

What printing options are available?

We support screen printing, heat transfer, gravure printing (laminated bags), and ultrasonic-embossed logos depending on the bag type.

What is your MOQ (Minimum Order Quantity)?

Our MOQ generally starts from 5,000 pcs per design, but we offer flexibility depending on the customization and material type.

Can I get a sample before mass production?

Absolutely. We offer free stock samples, and custom samples can be made for a small fee that is refundable upon bulk order.

What is your production lead time?

Production usually takes 15–25 days after sample approval, depending on the quantity and customization complexity.