Polypropylene, or PP, is a type of plastic you see almost everywhere. It is used in food containers, medical supplies, car parts, textiles, shopping bags, and even heavy-duty tool bags. People choose it because it is light, tough, and affordable.

One key thing to know about PP is its melting point, which sits around 160–170 °C (320–338 °F). That means it can handle boiling water without a problem, but at higher heat it will soften and eventually melt. This matters a lot in how products are made, how long they last, and how safe they are to use. At Initi bag, we pay close attention to this when designing strong, eco-friendly bags that hold up in real life.

What Is Polypropylene?

Polypropylene is a thermoplastic polymer made by polymerizing propylene monomers. It belongs to the polyolefin family, which also includes polyethylene (PE). Unlike natural fibers like cotton or wool that grow organically, polypropylene is man-made in chemical plants through polymerization processes.

Key Features of Polypropylene

- Lightweight – Less dense than many other plastics.

- Durable – Strong impact resistance and wear resistance.

- Heat-resistant – Handles hot liquids better than polyethylene.

- Moisture-resistant – Repels water naturally.

- Cost-effective – Cheaper to produce than many engineering plastics.

- Recyclable – Can be re-melted and reused multiple times.

Because it is both tough and versatile, PP is used in everything from food containers and packaging films to non-woven shopping bags, woven PP sacks, and industrial tote bags.

The Melting Point of Polypropylene Explained

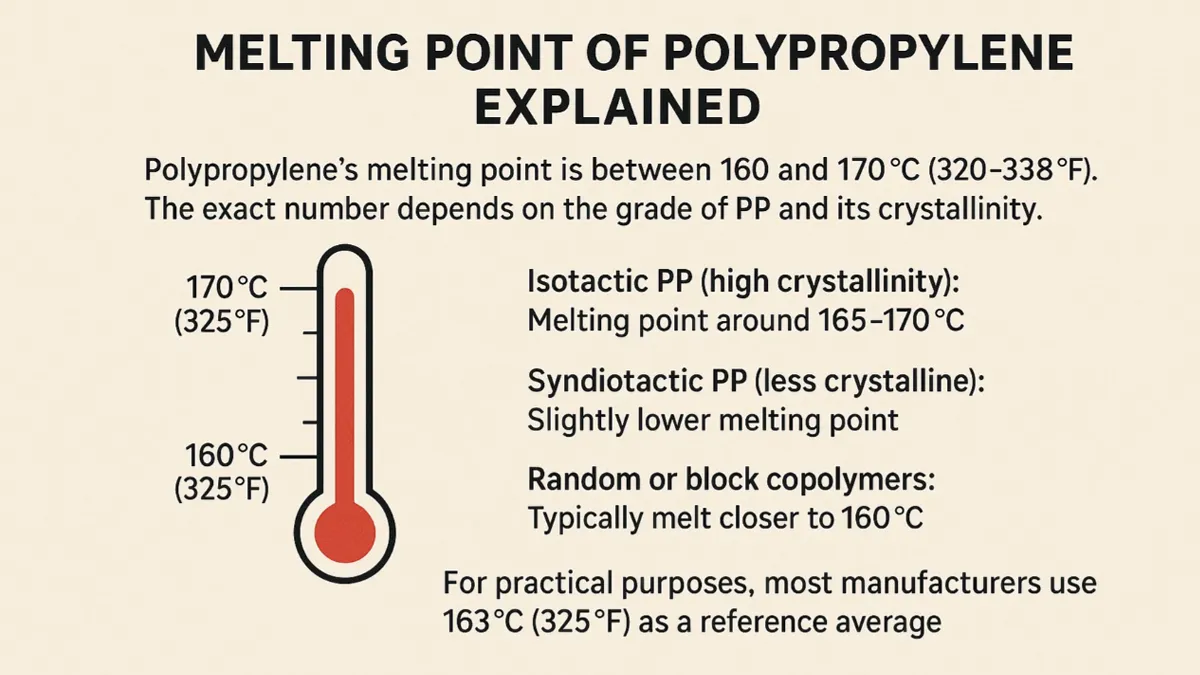

Polypropylene’s melting point is between 160 and 170 °C (320–338 °F). The exact number depends on the grade of PP and its crystallinity.

- Isotactic PP (high crystallinity): Melting point around 165–170 °C.

- Syndiotactic PP (less crystalline): Slightly lower melting point.

- Random or block copolymers: Typically melt closer to 160 °C.

For practical purposes, most manufacturers use 163 °C (325 °F) as a reference average.

Melting Point vs. Softening Temperature

It’s important to distinguish between melting point and softening point:

- Melting Point: When the polymer transitions from solid to liquid.

- Softening Point (Vicat temperature): When the material becomes soft enough to deform under stress. For PP, this is typically around 100–120 °C.

This means polypropylene bags can handle boiling water (100 °C) but may deform if exposed to an oven or a hot surface above 120 °C.

Factors That Affect Polypropylene Melting Point

Not all polypropylene melts at exactly the same temperature. Several factors influence the range:

1. Crystallinity

The more crystalline the structure, the higher the melting point. Isotactic PP, with its neat molecular order, melts hotter and feels stronger. Atactic PP is less crystalline, melts lower, and ends up softer. That is why some PP products hold shape better under heat while others feel more flexible.

2. Polymer Type

Homopolymer PP has a higher melting point and stiffness, so it is great for rigid parts. Random copolymer is softer, more flexible, and melts lower, making it good for packaging or products needing toughness. Block copolymer balances strength and impact resistance with only a slight drop in heat stability.

3. Molecular Weight

Heavier molecular chains need more energy to break, so high molecular weight PP usually melts at a higher temperature. Lighter chains melt more easily but can be easier to process. Manufacturers pick grades depending on whether strength or easier molding is the priority.

4. Additives and Fillers

Stabilizers, flame retardants, UV absorbers, and fillers like talc can change PP’s heat behavior. Some additives boost heat resistance, others make the material easier to melt or shape. This is why PP used outdoors or in food-safe products is not always exactly the same.

5. Processing Conditions

Slow cooling after molding gives PP more time to form crystals, which raises the melting point and makes it stiffer. Rapid cooling reduces crystallinity, creating a softer material with a lower melting point. The same resin can feel very different depending on how it is processed.

6. Thermal History

Repeated heating and cooling cycles can slowly damage PP’s structure, lowering its effective melting point. This is common in recycled PP, which may not perform quite like virgin material. Over time, even everyday heat exposure can reduce stability.

Comparison: Polypropylene vs Other Plastics

One way to understand polypropylene better is to compare its melting point with other common plastics.

| Polymer | Melting Point (°C) | Notes |

|---|---|---|

| Polypropylene (PP) | 160–170 | Lightweight, versatile, widely used in bags and packaging. |

| Polyethylene (LDPE) | 105–115 | Lower melting point, flexible, used in films and bags. |

| High-Density Polyethylene (HDPE) | 120–137 | More rigid than LDPE, used in bottles and containers. |

| PET (Polyethylene Terephthalate) | ~250 | Used in bottles, polyester fibers, high-temperature resistant. |

| Nylon (Polyamide) | 220–260 | High-performance plastic, used in engineering and textiles. |

| PVC (Polyvinyl Chloride) | 100–260 (varies) | Wide range depending on additives. |

Compared to polyethylene, polypropylene can handle higher heat, making it more suitable for hot food containers or heat-sealed bags.

Why the Melting Point Matters

Understanding polypropylene’s melting point is not just a scientific curiosity—it has real-world importance in:

1. Manufacturing

- Injection molding machines must heat PP above its melting point but not too much, to avoid degradation.

- Heat sealing in bag production requires precise temperature control.

2. Durability and Safety

- Bags need to resist hot environments (like being left in a car trunk in summer).

- Food containers must handle boiling water or microwaves.

3. Storage and Transport

- During shipping, products must remain stable even in warm climates.

4. Recycling and Sustainability

- Knowing PP’s melting point helps recyclers reprocess plastic efficiently without burning it.

Polypropylene in Bag Manufacturing

At Initi bag, polypropylene is one of our most important materials. We use it to produce a wide range of bags, from lightweight non-woven totes to heavy-duty woven sacks.

Why Polypropylene Works for Bags

- High strength-to-weight ratio – Strong but light.

- Stable under heat – Keeps shape in hot conditions up to ~120 °C.

- Shrink-resistant – Unlike cotton, PP does not shrink in washing.

- Heat-sealable – Can be bonded with ultrasonic welding or thermal pressing.

- Cost-effective – Perfect for mass production and promotional use.

- Eco-friendly option – Recyclable and reusable.

Types of Bags Made from Polypropylene

- Non-Woven PP Shopping Bags

These are probably the most common polypropylene bags you see every day. They are lightweight, reusable, and have become a popular eco-friendly alternative to single-use plastic bags. Because they are made with non-woven PP fabric, they can be produced in many colors and styles, often with custom printing for branding. They are perfect for supermarkets, trade shows, and promotional giveaways. - Woven PP Sacks

Woven polypropylene sacks are much stronger than they look. The fabric is made by weaving PP threads together, which gives them excellent durability and load-bearing capacity. That is why they are widely used for packaging heavy items such as rice, flour, animal feed, sand, or other industrial goods. They resist tearing, and thanks to polypropylene’s heat resistance, they can handle rough storage and transport conditions. - Laminated PP Bags

When extra durability and water resistance are needed, laminated PP bags are the go-to option. These bags have a thin film coating that makes them not only stronger but also resistant to moisture and dirt. They are often used for outdoor applications, shopping in wet conditions, or for products that need extra protection. The glossy or matte finish also makes them look more premium, which is great for retail use. - Custom OEM Bags

Polypropylene is versatile, which makes it perfect for custom designs. OEM bags can be tailored for branding, retail, or promotional campaigns. Businesses love them because they can choose the size, color, handle type, and printing method to match their image. From promotional giveaways to high-volume retail bags, custom PP bags offer flexibility and cost efficiency.

A key reason these different types of bags are possible comes down to polypropylene and its melting point. Because PP can be heat sealed, the bags can be made without stitching. This gives them strong seams, a clean finish, and helps keep production costs lower. That combination of strength and efficiency is what makes polypropylene one of the most reliable materials in bag manufacturing.

Heat Resistance and Limitations

Even though PP’s melting point is high, there are still limits:

- Long-term exposure above 120 °C can cause warping.

- At 160–170 °C, polypropylene melts completely.

- Above 200 °C, it begins to degrade and lose properties.

This is why polypropylene is perfect for boiling water applications, but not for ovens.

Practical Guidelines for Choosing Polypropylene Grades

When you are picking the right type of polypropylene for bags or other products, the grade really matters. Each type has its own strengths, and knowing the differences can help you get the right balance of durability, flexibility, and cost.

- Homopolymer PP

This is the purest form of polypropylene, made only from propylene units. It has a slightly higher melting point, which makes it stronger and stiffer. That is why it is often used in rigid products or bags that need to hold their shape. The trade-off is that it can feel less flexible, so it is not always the best choice if softness or stretch is a priority. - Copolymer PP

Copolymer PP mixes propylene with a small amount of another monomer. This lowers the melting point a little but makes the material more impact resistant and flexible. It is a smart option for bags that need to bend, fold, or carry heavy items without cracking. The extra toughness often makes it more versatile than homopolymer PP. - Food-Grade PP

When products are going to be used with food or beverages, food-grade PP is the safe choice. It is certified to meet strict safety standards and will not release harmful chemicals when exposed to hot liquids. That is why you see it in food containers and reusable grocery bags. For brands that want consumer trust, this grade is a must. - UV-Stabilized PP

Standard PP can break down or fade if it is exposed to direct sunlight for long periods. UV-stabilized PP solves this problem by adding special stabilizers that protect it from ultraviolet rays. This type is perfect for outdoor bags, beach totes, or agricultural sacks that need to last in sunny conditions without getting brittle. - Recycled PP

Recycled polypropylene is becoming more popular as sustainability grows in importance. It gives used PP a second life and reduces waste. While it may not always have the exact same thermal properties as virgin PP, it is still durable and works well in many applications. For eco-conscious brands, recycled PP is a strong option that balances performance with responsibility.

Conclusion

Polypropylene’s melting point of 160–170 °C (320–338 °F) is one of the key reasons why it has become a global favorite material. It offers durability, flexibility, recyclability, and heat stability—all at a low cost.

For bag manufacturing, this property makes polypropylene ideal for eco-friendly shopping bags, woven sacks, tool bags, and custom promotional products. It can withstand everyday use, resist heat, and be processed efficiently with heat sealing.

FAQs

What is the exact melting point of polypropylene?

Polypropylene typically melts between 160 and 170 °C (320–338 °F). The exact number depends on crystallinity, molecular structure, and additives. In most cases, manufacturers use around 163 °C as the benchmark.

Can polypropylene handle boiling water?

Yes. Since boiling water is 100 °C, well below the 160 °C melting point, PP remains stable. That’s why many food containers and non-woven shopping bags made of PP are safe with hot liquids.

What happens if polypropylene is heated above its melting point?

It will begin to soften, lose shape, and eventually liquefy. This is useful in manufacturing when PP needs to be molded, but dangerous if a finished product is accidentally exposed to extreme heat.

Is polypropylene microwave safe?

Most PP products are safe in the microwave because the temperature does not reach the melting point. However, always check the label, as some PP may contain additives not suited for high-heat food contact.

How does polypropylene’s melting point affect bag durability?

Bags made with polypropylene remain stable in everyday conditions—even when left in a hot car or used to carry hot food. The melting point ensures they don’t shrink, warp, or lose strength under normal use.