You might wonder what is nylon fabric and how you get it. Nylon fabric is a strong, smooth material that comes from chemicals found in oil. You see it everywhere, from clothes to bags. Factories mix special acids and turn them into long chains, then spin those chains into threads. Did you know that in 2023, people made over 1.2 million metric tons of nylon fabric worldwide? That shows how popular it is.

Key Takeaways

- Nylon fabric is strong and light. It is made from chemicals that come from oil.

- The way nylon is made uses polymerization. This makes long chains called polyamides.

- Nylon lasts a long time. It is great for clothes, bags, and outdoor gear.

- This fabric does not let water in easily. It dries fast and keeps you comfy in light rain.

- Nylon is simple to take care of. You can wash it in a machine. It dries fast and saves you time.

- Nylon fabric can be used in many ways. It is found in sportswear and in things used for work.

- The way nylon is made lets people create different types. Each type works best for certain jobs and needs.

- Picking nylon gives you a fabric that is strong, bendy, and looks good for daily use.

What Is Nylon Fabric

Simple Definition

If you ask what nylon fabric is, you want a simple answer. Nylon fabric is made by people using chemicals from coal and petroleum. Factories use a special process called polymerization. This process changes the chemicals into long chains called polyamides. The result is a strong, smooth, and bendable fabric. It feels light and lasts a long time. In textile science, experts call nylon a synthetic fiber. This means it does not come from plants or animals. Instead, scientists make it in a lab by mixing chemicals.

- Nylon fabric is made from carbon-based chemicals.

- The process uses polymerization to build a strong polymer.

- The result is a synthetic fiber called polyamide.

Main Characteristics

When you touch nylon fabric, you notice some things right away. Let’s look at the main features that make it special.

Durability

You want your clothes and bags to last long. Nylon fabric is very durable. It can handle lots of stress and tough use. The material has great tensile strength, between 6,000 and 12,000 psi. You can pull and stretch it, and it will not break easily. Nylon also resists wear and rubbing, so it works well for things you use often.

Lightweight

If you pick up a jacket or backpack made from nylon, it feels light. The fibers are thin but strong. You get less weight but still have toughness. This makes nylon good for outdoor gear, sportswear, and travel bags. You do not feel heavy, even with a full bag.

Water Resistance

You may wonder if nylon fabric keeps you dry. Nylon gives moderate water resistance. Water does not soak in fast, so you stay comfortable in light rain. The fibers do not take in much moisture, usually less than 5%. Nylon is not fully waterproof, but it dries quickly and does not hold water like cotton.

Here’s a quick look at some physical and chemical characteristics:

| Characteristic | Description |

|---|---|

| Tensile Strength | Very strong (6,000–12,000 psi) |

| Elasticity | Goes back to shape after stretching |

| Flexibility | Bends without breaking |

| Abrasion Resistance | Does not wear out or rub away easily |

| Chemical Stability | Stays strong against oils, greases, and weak acids |

Nylon vs Other Fabrics

You may ask how nylon fabric compares to other materials. Let’s see some key differences.

| Material | Tensile Strength (MPa) | Elongation at Break (%) | Abrasion Resistance | Moisture Absorbency |

|---|---|---|---|---|

| Nylon | 75–90 | 20–30 | Excellent | <5% |

| Cotton | 3–6 | 5–10 | Moderate | 7–8% |

Nylon fabric is strong and does not absorb much water. Cotton feels soft but takes in more water and wears out faster. Polyester is another synthetic fabric you see a lot. It resists water better than nylon but does not stretch as much. Nylon gives you high durability and elasticity. Polyester offers better water resistance but less stretch.

- Nylon is strong and stretchy, with moderate water resistance.

- Polyester does not absorb much water and works well when wet.

- Cotton feels soft but holds more water and wears out faster.

So, if you choose nylon fabric, you get a tough, light material that dries fast. You see it in jackets and backpacks because it works well for daily use and changing weather.

Nylon Fabric Raw Materials

When you see polyamide fabric, you might not know what it’s made from. Let’s look at the basic things used to make this strong material.

Petrochemicals and Crude Oil

Polyamide fabric starts with crude oil. Factories break crude oil into smaller parts called petrochemicals. These petrochemicals are the building blocks for polyamide fabric. They help make many synthetic materials. Without crude oil, you could not make nylon.

Diamine Acid and Adipic Acid

After getting petrochemicals, factories turn them into special chemicals. Two important ones are diamine acid and adipic acid. These chemicals help make polyamide fabric. When you mix adipic acid with hexamethylenediamine, they react together. This reaction is called condensation polymerization. It forms long chains of nylon molecules. These chains make polyamide fabric strong and tough. Adipic acid also helps control the size of nylon molecules. This lets factories change the fabric for different uses. You might want tough polyamide fabric for backpacks. You might want soft polyamide fabric for clothes.

Tip: Mixing diamine acid and adipic acid in different ways can change how polyamide fabric feels and works.

Polyamide Structure

Let’s see why polyamide fabric is so tough. The secret is in its structure. Polyamide fabric has long chains of molecules linked tightly. This makes the fabric strong and bendable. Here are some key properties:

| Property | Description |

|---|---|

| Abrasion Resistance | Polyamide’s special structure helps it resist wear. |

| Impact Resistance | Flexible chains spread energy when hit, so it does not break easily. |

| Temperature Stability | Stays bendable in cold and handles heat well, so it lasts longer. |

When you pick polyamide fabric, you get something that can handle rough use. It can take hits and changes in temperature. That’s why polyamide fabric is used in sports gear and outdoor equipment. The strong structure helps your things last longer and look good.

How Nylon Fabric Is Made

Polymerization Process

You may wonder how polyamide fabric is made. It starts with a chemical reaction called polymerization. Factories use special chemicals like hexamethylene diamine and adipic acid. These chemicals come from crude oil and petrochemicals. Workers mix them in safe, controlled places. This is when the process begins.

Creating Nylon Polymers

Let’s look at the steps:

- Preparation of Monomers: You need two main chemicals. They are hexamethylene diamine and adipic acid. These chemicals are the building blocks for polyamide fabric.

- Polymerization Reaction: The monomers are heated with a catalyst. Water leaves as the chemicals join together.

- Polymer Chain Formation: The reaction goes on for hours. The monomers link up and form long chains. These chains make polyamide fabric strong and flexible.

- Cooling and Solidification: When the chains are long enough, the mixture is cooled. It becomes solid nylon, ready for the next step.

Here is a simple table showing the chemical reactions:

| Nylon Type | Reaction Type | Reactants | By-product |

|---|---|---|---|

| Nylon 6,6 | Condensation | Adipic acid, Hexamethylenediamine | Water |

| Nylon 6 | Ring-opening | Caprolactam | N/A |

You get polyamide fabric with different features. It depends on the reaction and chemicals used. Nylon 6,6 is known for being strong and lasting a long time.

Spinning into Fibers

After making solid nylon polymer, it must become fibers. This step is important for making nylon fiber. Factories use machines to melt the nylon. They push it through tiny holes called spinnerets. The melted nylon comes out as long, thin threads.

Extrusion and Drawing

Here is how strong polyamide fabric fibers are made:

- Spinning machines melt nylon and push it through spinnerets. Machines like 1200/4/8 and 1400/6 do this job. They can make different sizes, from 500D to 850D and more.

- The threads cool down and become solid quickly. The fibers are stretched over heated rollers. This step is called drawing.

- Drawing lines up the molecules inside each fiber. The fibers become stronger, more stretchy, and resist wear.

- Heat setting helps the fibers keep their shape and strength.

Tip: Drawing makes polyamide fabric tough and stretchy. This helps sportswear, bags, and outdoor gear work better.

Weaving and Knitting

Now you have strong nylon fibers. They must be made into fabric you can use. Factories use weaving and knitting machines for this. There are many types of polyamide fabric. Each type looks and feels different.

Forming the Fabric

Here are some common ways to make fabric:

| Technique | Type | Characteristics | Common Uses |

|---|---|---|---|

| Taffeta | Woven | Tight weave, blocks wind and water | Umbrella canopies, jacket linings |

| Ripstop | Woven | Grid pattern, stops tears, extra strong | Tents, parachutes |

| Dobby | Woven | Small patterns, adds texture and strength | Shirting, upholstery |

| Tricot | Knitted | Smooth surface, very stretchy | Lingerie, swimwear |

| Circular Weft Knit | Knitted | Stretches four ways, comfy for movement | T-shirts, workout gear |

| Mesh | Knitted | Open holes, lets air flow | Sports apparel |

| Power-Net | Knitted | Support fabric, lets air in | Medical braces, sports apparel |

You get polyamide fabric for many needs. Some are tough for tents. Some are soft for shirts. The way fibers are woven or knitted changes how the fabric feels and works.

If you choose nylon, you get strong, flexible, and light material. Nylon fiber production gives you many choices for clothes, bags, and outdoor gear.

Heat and Pressure Steps

When you look at nylon fabric, you might not think about the heat and pressure it went through. These steps make a big difference in how your jacket or backpack feels and lasts. Factories use heat and pressure to lock in the shape and strength of nylon fibers. You get fabric that stays smooth, resists wrinkles, and holds up over time.

Here’s what happens during these steps:

- Machines heat the nylon fibers to a set temperature. This is called heat setting.

- The fibers get pressed or stretched while hot. This helps them keep their shape.

- Sometimes, workers add steam or moisture. This stops the fabric from turning yellow or changing color.

- The timing matters. If you heat the fibers for too long, they can get weak. If you cool them too fast, they might lose strength.

- Cooling comes last. It protects the structure and makes the fabric tough.

Tip: Heat and pressure steps help your nylon gear stay wrinkle-free and last longer, even after many washes.

Let’s see how each part of the process affects the quality of nylon fabric:

| Aspect | Influence on Quality |

|---|---|

| Heat Setting | Stabilizes dimensions, improves wrinkle resistance |

| Temperature Control | Prevents fiber damage and yellowing |

| Moisture/Steam | Prevents oxidation and color change during heat setting |

| Timing | Ensures proper molecular bond strengthening |

| Cooling | Protects fabric structure and enhances durability |

You want your nylon clothes and bags to look good and work well. Heat and pressure steps make sure the fabric stays strong, smooth, and flexible. Next time you grab your nylon backpack, remember that heat and pressure helped make it ready for your adventures.

Finishing Nylon Fabric

Dyeing and Coloring

When you look at a bright jacket or a colorful backpack, you might wonder how it gets its color. Dyeing nylon fabric is a careful process. Factories use several methods to make sure the color sticks and looks even. You start with pretreatment, which cleans the yarn and gets it ready for dye. Then, you have a few options for adding color:

- One-bath dyeing works well when you mix nylon with cotton.

- The active plus acid one-bath two-step method helps when you want strong colors.

- Sometimes, you dye cotton first and then nylon in a two-bath process.

- You can also dye nylon first and then cotton, depending on the look you want.

For pure nylon, you see methods like immersion dyeing, jet dyeing, and warp dyeing. Immersion dyeing lets the yarn soak in the dye bath, so the color goes deep. Jet dyeing sprays dye onto the yarn, which works fast and gives good color fastness. Warp dyeing keeps the yarn stretched, so you get even color along long threads.

Tip: Jet dyeing is great for mass production because it colors lots of fabric quickly and evenly.

Texture and Performance Treatments

You want your nylon gear to feel good and work well. Factories use special treatments to change how the fabric feels and performs. These treatments add benefits like waterproofing, toughness, and breathability. Here’s a quick look at some common options:

| Treatment Type | Benefits | Performance Impact |

|---|---|---|

| PU Coating | Flexibility, Waterproofing | Makes fabric quieter and more comfortable |

| PVC Coating | Toughness, Gloss | Adds durability and a shiny look |

| TPU Coating | Elasticity, Chemical Resistance | Helps fabric bounce back after stretching |

| DWR | Water Repellency | Keeps water out but lets air flow |

| Silicone | Heat and Weather Stability | Helps fabric last longer in tough conditions |

You might notice that some nylon feels smooth and quiet, like taffeta or tricot. These fabrics don’t rustle much, so they’re nice for jackets or linings. Ballistic nylon feels crinkly, but you know it’s strong and ready for rough use. Factories pick the right weave and coating to match what you need, whether it’s comfort or toughness.

Quality Control

You want your nylon gear to last and look good. Factories check every batch to make sure it meets high standards. They look at three main things:

- Structural Integrity

- They check fiber ratios. Even a small mistake can change how stretchy the fabric is.

- Yarn twist must stay consistent. This helps the fabric resist wear.

- Weaving or knitting density matters. It affects how see-through and breathable the fabric is.

- Functional Performance

- Stretch recovery should be at least 80% after thousands of pulls.

- Training gear needs to survive over 50,000 rubs without wearing out.

- Colorfastness is tested. The color should fade less than 1.5 units after many washes.

- Compliance

- Factories follow rules about chemicals and safety, like REACH and CPSIA.

- Sleepwear must pass flammability tests.

- Clothes that touch your skin need to be safe and comfortable.

Testing uses special methods. You see checks for stretch, strength, color, moisture, and weight. Some factories even get OEKO-TEX® certification to show their nylon fabric is safe for you to wear.

If you buy nylon gear from a trusted maker, you know it’s been tested for quality, safety, and performance.

Nylon Fabric Features

Strength and Flexibility

You want a fabric that can handle your busy life. Nylon fabric gives you both strength and flexibility. When you pull or stretch it, the fibers bounce back instead of breaking. This makes it perfect for things like backpacks, jackets, and sports gear. In tests, nylon stands out because it can take more force before tearing compared to other synthetic fabrics like polyester. You get a material that holds up under pressure and keeps its shape, even after lots of use.

- Abrasion testing checks how well the surface resists wear.

- Tear strength testing measures how much force it takes to rip the fabric.

- Tensile strength testing shows how much pulling the fabric can handle.

Cordura nylon is famous for being extra tough. You often see it in outdoor gear because it can survive rough weather and heavy use.

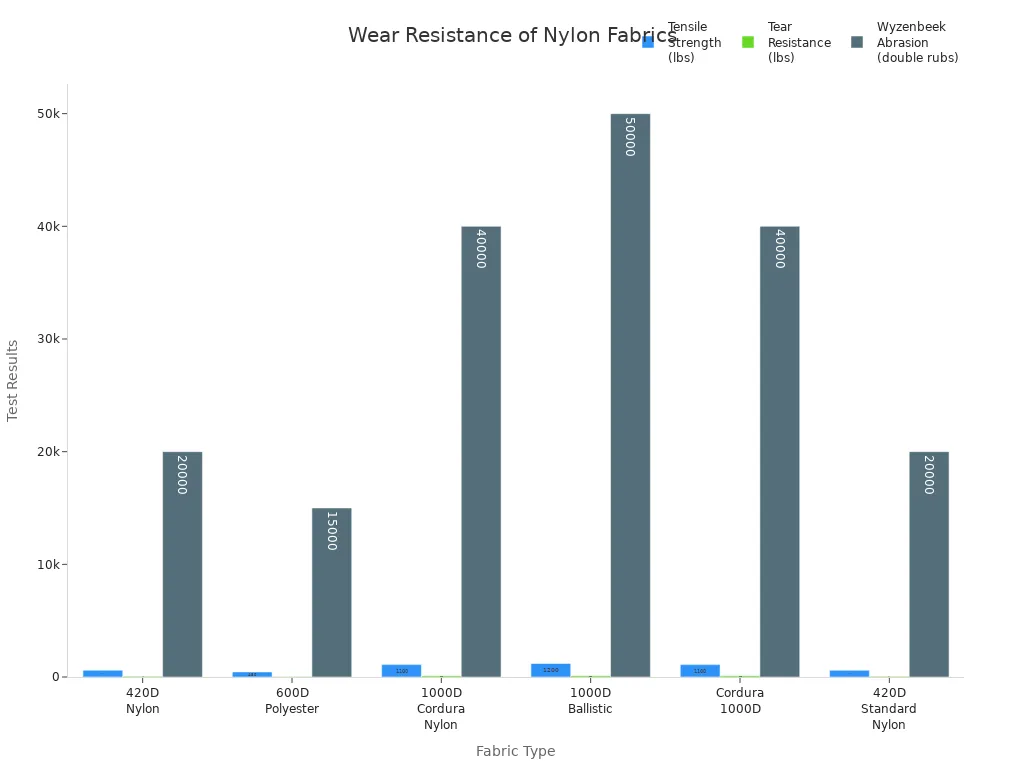

Wear Resistance

You probably want your gear to last a long time. Nylon fabric does a great job here. It resists scratches, scuffs, and tears better than many other materials. Take a look at how it compares in the lab:

| Fabric Type | Tensile (lbs) | Tear (lbs) | Wyzenbeek (double rubs) |

|---|---|---|---|

| 1000D Ballistic | 1,200 | 120 | 50,000 |

| Cordura 1000D | 1,100 | 115 | 40,000 |

| 420D Standard Nylon | 600 | 60 | 20,000 |

| 600D Polyester | 450 | 50 | 15,000 |

You can see that nylon, especially the ballistic and Cordura types, scores high in all the tests. This means your nylon backpack or jacket can handle lots of rubbing, pulling, and even rough treatment without falling apart.

Tip: If you want something that lasts, choose nylon for your outdoor adventures or daily use.

Easy Care

You don’t want to spend hours taking care of your clothes or bags. Nylon makes life simple. You can wash most items in the machine using cool or warm water and a gentle cycle. For delicate things like hosiery, hand-wash or use a mesh bag. Nylon dries quickly, so you don’t have to wait long before using your gear again.

Here’s a quick care guide:

| Care Instruction | Details |

|---|---|

| Washing | Machine wash cool, gentle |

| Bleaching | Non-chlorine bleach as needed |

| Drying | Tumble dry low, delicate |

- Use fabric softener to cut down on static.

- Tumble-dry on low heat.

- Press with a cool iron if needed.

Nylon fabric is easy to keep clean and looking new, so you can spend more time enjoying your favorite activities.

Uses of Nylon Fabric

Clothing and Apparel

You see nylon fabric in lots of clothing and apparel. If you wear a windbreaker or a rain jacket, you probably notice how light and smooth it feels. Sportswear brands use nylon in running shorts, leggings, and swimwear because it stretches and dries fast. You might find nylon in socks, tights, and even underwear. This fabric helps keep you comfortable when you move or sweat. Designers like nylon for its bright colors and shiny look. You get stylish apparel that stands out and lasts longer than cotton. Some uniforms and workwear also use nylon because it resists stains and holds up after many washes.

Did you know? Many athletic apparel companies choose nylon for its strength and flexibility. You get gear that moves with you and stays tough.

Bags and Accessories

You probably carry something made from nylon every day. Backpacks, tote bags, and travel luggage often use nylon fabric because it handles heavy loads and rough treatment. If you own a wallet or a belt, there’s a good chance it has nylon inside. Outdoor brands use nylon for hiking packs and duffel bags since it resists tearing and keeps water out. You see nylon in umbrellas, watch straps, and even hats. These accessories stay light and easy to clean. When you pick a nylon bag, you get a product that lasts through school, work, or travel.

Here’s a quick table showing popular nylon accessories:

| Accessory | Why Nylon Works Well |

|---|---|

| Backpack | Tough, resists abrasion |

| Umbrella | Water-repellent, lightweight |

| Wallet | Flexible, holds shape |

| Belt | Strong, doesn’t stretch out |

| Hat | Breathable, easy to wash |

Industrial and Outdoor Uses

Nylon fabric isn’t just for clothes and bags. You find it in many industrial and outdoor products. If you go camping, you might sleep in a tent made from ripstop nylon. This material stands up to wind and rain. Factories use nylon in conveyor belts because it’s strong and doesn’t wear out quickly. Tarpaulins made from nylon protect goods during shipping and storage, even in bad weather. Parachutes and safety nets rely on nylon for their strength and tear resistance. When you hike or travel, your backpack probably uses nylon for extra durability.

- Tents: Stay strong and keep out rain, especially with ripstop nylon.

- Backpacks: Handle heavy loads and rough use, trusted by outdoor brands.

- Conveyor Belts: Move products in factories, last a long time.

- Tarpaulins: Cover and protect items, work well in harsh weather.

- Parachutes and Safety Nets: Keep people safe, resist tearing.

If you need gear for work or adventure, nylon fabric gives you the reliability you want. You get products that perform well in tough conditions and last for years.

Why Nylon Fabric Is Made This Way

Benefits of the Process

Factories use a special process to make polyamide fabric. This process gives the fabric many good qualities. Each step adds something important. The result is a material that stands out from other synthetic fabrics.

Here’s a table showing the main advantages compared to other synthetic fabrics:

| Benefit | Description |

|---|---|

| Strength and Durability | High tensile strength and resistance to wear, perfect for outdoor gear and industrial parts. |

| Chemical Resistance | Handles oils and solvents, useful in automotive and medical fields. |

| Low Friction Coefficient | Smooth fibers work well for textiles, carpets, and ropes. |

| Heat Resistance | Stays strong at high temperatures, good for tires, airbags, and seat belts. |

| Moldability | Easily shaped for different plastic products. |

| Elasticity | Bounces back to shape, popular in sports equipment and outdoor wear. |

| UV Resistance | Some protection from sunlight, great for outdoor environments. |

| Dyeability | Takes color easily, so you get bright and lasting shades. |

You get these benefits because the process controls the structure. Factories can change the steps to make the fabric stronger or stretchier. They can also make it more colorful. This means polyamide fabric is used in many things, like backpacks and medical gear.

If you want a fabric that lasts, resists chemicals, and looks good, the way polyamide fabric is made gives you those benefits.

There are some downsides too. Polyamide fabric can melt if it gets very hot. It might pill or snag if you use it roughly. Some people notice it can hold smells after heavy use. These problems matter if you need gear for tough jobs or want something that always smells fresh.

Impact on Features and Uses

How polyamide fabric is made affects what it can do. You see this when you pick up a nylon jacket or backpack. Polymerization and extrusion steps make polyamide fabric strong. It resists wear and lasts through hard use. The fabric stretches, so your clothes move with you. This is great for sportswear and active gear.

Factories design polyamide fabric to pull moisture away from your skin. You stay dry during workouts or rainy days. The smooth fibers feel soft and do not rub your skin. The fabric takes dye well, so you get bright colors. This makes polyamide fabric popular for stylish clothes and accessories.

Let’s look at some advantages and disadvantages you might notice:

- Advantages

- Lasts longer than cotton or polyester.

- Stays strong after many washes.

- Handles sun and rain outside.

- Feels light and stretches for comfort.

- Disadvantages

- Can melt if it gets very hot.

- May pill or snag with rough use.

You see nylon fabric in sportswear, outdoor gear, industrial products, and fashion. The process gives you a fabric that works for many needs. If you want something tough, flexible, and easy to care for, polyamide fabric is a smart choice.

Conclusion

You now know nylon fabric starts with chemicals from oil. Factories turn these into strong, flexible threads using these steps:

- Extract monomers from petroleum.

- Polymerize to form polyamide chains.

- Melt and extrude into filaments.

- Draw and wind the fibers.

You see nylon in sportswear, swimwear, and bags because it dries fast, stretches, and keeps its color. Here’s why nylon works great for custom bags:

| Advantage | Description |

|---|---|

| Softness and Appearance | Feels smooth and looks shiny |

| Stretchability | Stretches without breaking |

| Strength to Weight Ratio | Strong but light |

We make custom nylon bags with OEM and ODM services. Want a bag that lasts? Reach out and let’s create your perfect solution together!

FAQ

What makes nylon fabric different from polyester?

Nylon feels softer and stretches more than polyester. You get better elasticity and abrasion resistance with nylon. Polyester dries faster and resists water better. Both work well for bags and clothes, but nylon gives you extra strength and flexibility.

Can you wash nylon fabric in a washing machine?

Yes, you can toss nylon clothes or bags in your washing machine. Use cool or warm water and a gentle cycle. Nylon dries quickly, so you spend less time waiting. Always check the care label for best results.

Is nylon fabric safe for sensitive skin?

You can wear nylon if you have sensitive skin. Most nylon fabrics feel smooth and don’t cause irritation. Some people may react to dyes or finishes, so choose OEKO-TEX® certified nylon for extra safety.

Does nylon fabric shrink or stretch out over time?

Nylon holds its shape well. You won’t see much shrinking or stretching after washing. The fibers bounce back, so your clothes and bags stay looking new. Avoid high heat to keep nylon strong.

How do you remove stains from nylon fabric?

You can clean stains with mild soap and water. Gently rub the spot with a soft cloth. For tough stains, use a little non-chlorine bleach. Always test on a small area first to avoid damage.

What are the most common uses for nylon fabric?

You see nylon in jackets, backpacks, tents, umbrellas, and sportswear. Outdoor brands love nylon for its strength and light weight. You also find it in belts, wallets, and industrial products.