You want your custom apparel to stand out, so picking the right printing methods matters. When you compare printing methods for custom bags, most people find DTF works better than DTG. DTF gives you strong print quality, great durability, and works on more materials. Both printing methods have unique strengths, but DTF handles more custom apparel projects and lasts longer on bags. If you care about real-world results, looking at dtg vs dtf printing side by side helps. These printing methods can change how your custom apparel looks and feels, so let’s break down what really works for you.

Key Takeaways

- DTF printing is usually stronger and more flexible than DTG. This makes it good for many types of bag materials.

- Choose DTG printing if you want detailed designs on 100% cotton bags. DTG gives soft and high-quality prints.

- DTF printing lets you use bright colors on many fabrics. It works on polyester and nylon without needing pre-treatment.

- Both methods make colors look bright. But DTF keeps its colors bright for a longer time.

- DTG is cheaper for small orders. DTF saves money on setup and is better for big orders.

- Think about the fabric type before picking a printing method.

- DTG works best on natural fibers. DTF is better for blends and synthetic fabrics.

- The print finish changes how the bag looks. DTG gives a soft feel. DTF makes the print bold and bright.

- Talk to experts to find the best printing method for your project.

DTG Printing

Overview

If you want to print detailed designs on custom bags, dtg printing is a popular choice. DTG stands for direct-to-garment printing. This method uses a special printer to spray ink right onto the fabric. You get sharp images and smooth color blends. DTG printing works best for small orders and designs with lots of detail. Many people like it because it feels soft and looks great on cotton bags.

How It Works

You might wonder how direct-to-garment printing actually works. Here’s a simple breakdown:

| Step | Description |

|---|---|

| Pre-treatment | You treat the fabric before printing. This helps the ink stick better and last longer. |

| Printing | The printer sprays water-based ink directly onto your bag. |

| Post-processing | You cure the ink, usually with heat, to make the print durable. |

This process is much faster to set up than screen printing. You don’t need to make stencils or screens for each color. You just upload your design and print.

Tip: DTG printing is perfect if you want to print a photo or a design with lots of colors and shading.

Pros and Cons

Quality

DTG printing gives you high-quality prints, especially on natural fabrics like cotton. You can print photos, gradients, and tiny details. The print feels soft and blends into the fabric. Many users say the results look professional and sharp.

Durability

You want your custom bag to last. DTG prints usually last about 40 to 50 washes if you take care of them. The print may fade faster if you wash the bag often or use harsh detergents. DTG printing is not as durable as some other methods, but it holds up well for most everyday use.

Colors

With dtg printing, you can use as many colors as you want. The printer can handle full-color images and smooth gradients. You don’t have to worry about extra setup for each color. This makes direct-to-garment printing great for colorful, detailed artwork.

Fabrics

DTG printing works best on 100% cotton bags. The ink soaks into natural fibers and gives a soft feel. It does not work as well on polyester, nylon, or blends. If you want to print on canvas or cotton, dtg printing is a strong choice.

Cost

For small orders, dtg printing is cost-effective. You don’t pay extra for each color, and setup is quick. If you need a large batch, the cost can add up because the ink is expensive. The pre-treatment step also takes extra time.

Flexibility

You can print one bag or a dozen with dtg printing. It’s flexible for small runs and custom designs. You can change your artwork for each bag without extra cost or setup.

Finish

The finish of dtg printing feels soft and lightweight. The ink blends into the fabric, so your bag stays flexible. The print does not crack or peel, but it may fade over time with heavy washing.

| Feature | DTG Printing | Screen Printing |

|---|---|---|

| Process | Digital, sprays ink directly onto fabric | Uses stencils for each color |

| Best for | Intricate designs, small batches | Larger runs, simpler designs |

| Ink Type | Water-based inks | Various inks, including specialty |

| Color Capability | Full-color images, gradients | Limited by stencil colors |

| Fabric Compatibility | Best on 100% cotton | Works on various fabrics, including synthetics |

| Setup Time | Quick setup for designs | Longer setup for creating stencils |

| Cost Efficiency | More cost-effective for small orders | More cost-effective for large orders |

| Print Feel | Soft feel, lightweight prints | Can be heavier depending on ink used |

- DTG printing is ideal for small, detailed orders.

- You get soft prints and can use many colors.

- The process is quick, but prints may fade faster with frequent washing.

DTF Printing

Overview

If you want a way to print on almost any bag, dtf printing is a great choice. Direct-to-film printing lets you make bright and detailed designs. You can use it on cotton, polyester, nylon, canvas, and even leather. You do not have to worry about what fabric you use. Dtf printing gives you lots of options and strong results. That is why many people like it for custom bags. Small businesses and designers pick dtf printing because it works for simple and hard designs.

How It Works

Dtf printing uses a special process. First, you print your design on a film. Then, you add a powder glue to the film. After you heat the film, you press the design onto your bag. You do not need to treat the fabric first, so you save time. You can make many transfers at once. This makes dtf printing good for both small and big orders.

Here is a quick chart to compare dtf printing and dtg printing:

| Feature | DTF Printing | DTG Printing |

|---|---|---|

| Fabric Compatibility | Untreated cotton, polyester, silk, denim, etc. | Pre-treated cotton, cotton/poly blends, some polyester |

| Setup Time | No pretreatment required | Requires pretreatment and drying |

| Production Time | 200-400% more productive due to roll-to-roll capability | Slower, requires manual loading/unloading of garments |

| Adhesive Requirement | Uses white powder adhesive for vibrant colors | Requires a base layer of white ink for color vibrancy |

| Equipment Cost | Generally lower, suitable for small businesses | Higher cost, especially for industrial-grade printers |

Tip: Dtf printing is great if you want to print on many types of bags without extra work.

Pros and Cons

Quality

Dtf printing gives you clear, high-quality prints. The edges look sharp and the colors stay bright. Your designs look nice, even after many uses. Direct-to-film printing keeps small details easy to see.

Durability

You want your custom bags to last a long time. Dtf printing makes prints that stay strong after many washes. On polyester bags, dtf printing keeps its color and shape better than dtg printing. Your designs do not fade or crack, so your bags look new for longer.

Colors

Dtf printing lets you use bright and bold colors. You can print full-color pictures, smooth color changes, and tiny details. The powder glue helps colors look bright on any fabric. Direct-to-film printing does not stop you from being creative.

Fabrics

You can use dtf printing on almost any fabric. Cotton, polyester, nylon, canvas, and blends all work well. You do not need to treat the fabric first. This makes dtf printing a top pick for all kinds of custom bags.

Cost

Dtf printing saves money, especially for small orders. You do not pay for extra setup because you skip treating the fabric. The machines cost less than dtg printers, so small businesses can start with less money. But you still need to buy special printers and heaters, which can cost a lot at first.

Flexibility

You can print one bag or many bags with dtf printing. The process works for both small and big orders. You can change your design for each bag without extra work. Direct-to-film printing lets you try new ideas.

Finish

Dtf printing makes a smooth, slightly raised print. The print feels soft but sits on top of the fabric. Your design stays flexible and does not crack. The finish looks bright and professional, so your custom bags stand out.

Here is a quick look at the main good and bad points:

| Advantages of DTF Printing | Disadvantages of DTF Printing |

|---|---|

| High-quality prints | Production speed limitations |

| Versatility across substrates | Maintenance requirements |

| Cost-effectiveness for short runs | Initial investment costs |

- High-quality prints with sharp edges and bright colors.

- Works on many materials like cotton, polyester, leather, and nylon.

- Saves money for small orders because there are no setup fees.

- Slower production speed, usually only 3–8 transfers per hour.

- Needs more care and cleaning than regular digital printing.

- You need to spend a lot at first for special equipment.

Dtf printing helps you make custom bags that last, look good, and fit any project.

DTG vs DTF Printing

Print Quality

You want your custom bags to look nice and professional. Both dtg and dtf printing give you great results. Direct-to-garment printing makes images that look like photos. The colors blend smoothly. DTF printing also gives sharp details and smooth color changes. Your designs will stand out on any bag.

Here is a quick chart to show how each method works:

| Printing Method | Print Quality Features |

|---|---|

| DTF | Sharp details and smooth gradients; great for small and large orders |

| DTG | Excellent photo-quality prints; best for complex, multicolor designs |

| Winner | Tie – Both offer high print quality depending on the use case |

If you want to print a detailed logo or a colorful photo, both dtg and dtf printing work well. The best choice depends on your bag’s material and your design.

Durability

You want your custom bags to last a long time. Durability is important when you compare dtg and dtf printing. DTF prints bend with the fabric and do not crack. This works even on rough bags like jute. The glue in DTF printing keeps the design bright and stuck on, even after many washes.

DTF prints on jute bags last a long time. They bend with the fabric and do not crack because the ink and glue are flexible. They do not scratch off easily, even though jute is rough. People say DTF prints on jute stay bright and stuck on with normal use.

Direct-to-garment printing also lasts well, especially on cotton bags. The ink goes into the fabric, so the print feels soft and stays after many washes. But dtf prints usually last longer on tough bags and with heavy use.

Color Vibrancy

You want your custom bags to have bright colors. Both dtg and dtf printing let you use many colors and smooth color changes. You do not need extra setup for small orders. You can print hard designs or full-color logos easily.

- Print many colors with smooth blends and photo detail

- No extra setup for small orders

- Great for hard designs or full-color logos

DTF printing makes colors look bright on any fabric. DTG printing looks best on cotton with deep, rich colors. If you want your design to stand out, both dtg and dtf printing give you lots of color choices.

Fabric Compatibility

When you pick a printing method for your custom bags, fabric compatibility matters a lot. Not every method works well on every material. Let’s break down how DTG vs DTF printing performs on the most common bag fabrics.

Cotton

If you love cotton bags, you’ll find DTG printing shines here. The ink soaks right into the natural fibers, giving you a soft and smooth finish. You get bright, detailed prints, especially on light-colored cotton. But DTG struggles with synthetic fabrics and dark cotton, where colors can look less vibrant.

- DTG works best on 100% cotton.

- You get soft prints that blend into the fabric.

- Colors may look dull on dark cotton.

DTF printing also handles cotton well. The design sits on top of the fabric, so you get bold colors even on dark cotton. You don’t need to pre-treat the bag, which saves you time.

- DTF prints look bright on both light and dark cotton.

- No pre-treatment needed.

Canvas

Canvas bags are popular for their strength and style. DTG can print on canvas, but only if it’s made from natural fibers. Synthetic canvas doesn’t hold DTG ink well. You might see faded colors or patchy prints.

- DTG works on natural canvas, not synthetic.

- Prints may fade faster on rough canvas.

DTF printing is a top choice for canvas bags. You get sharp, colorful designs that last. The print sits on the surface, so it stays bright and clear, even after heavy use.

- DTF works great on canvas and denim.

- You get durable, high-quality prints.

Polyester

Polyester bags are everywhere, but they can be tricky to print. DTG printing doesn’t bond well with polyester. The ink may wash out or look faded. If you want to print on polyester, DTF is the way to go.

- DTG is not recommended for polyester.

- Prints may not last or look vibrant.

DTF printing sticks to polyester with no problem. You get strong, colorful designs that hold up after many washes.

- DTF is perfect for polyester bags.

- Colors stay bright and prints last longer.

Nylon

Nylon bags are lightweight and water-resistant, but they don’t play nice with DTG printing. The ink can bead up or not stick at all. You’ll see poor results if you try DTG on nylon.

- DTG does not work on nylon.

- Ink won’t bond to the fabric.

DTF printing, on the other hand, works well on nylon. The adhesive powder in DTF helps the print stick, so your design stays put.

- DTF is a smart pick for nylon bags.

- Prints stay sharp and don’t peel off.

Blends

Many bags use fabric blends, like cotton-poly or canvas-nylon mixes. DTG printing struggles with blends, especially if there’s a lot of synthetic fiber. The print may look faded or wash out quickly.

- DTG works best with high-cotton blends.

- More synthetic fibers mean weaker prints.

DTF printing handles blends with ease. You get consistent, bright prints, no matter the mix.

- DTF works on almost any blend.

- You get reliable results every time.

Tip: If you want to print on a tricky fabric or a blend, DTF printing gives you more options and better results.

Quick Comparison Table

| Fabric Type | DTG Printing Compatibility | DTF Printing Compatibility |

|---|---|---|

| Cotton | Excellent (natural fibers only) | Excellent |

| Canvas | Good (natural canvas only) | Excellent |

| Polyester | Poor | Excellent |

| Nylon | Not compatible | Excellent |

| Blends | Fair (high cotton content needed) | Excellent |

You can see that DTF printing wins when you want to print on a wide range of bag materials. DTG is best if you stick with 100% cotton or natural canvas. For everything else, DTF gives you more freedom and better results.

Finish

When you print custom bags, the finish makes a big difference. You want your bag to look good and feel right. DTG and DTF printing both give you choices for how your bag will look. You can pick a matte finish if you want something soft and smooth. You can choose a glossy finish if you want your bag to shine and catch the light. Some printers even offer a textured finish for a unique touch. Both DTG and DTF let you decide what works best for your style.

DTG printing blends the ink into the fabric. Your bag feels soft and natural. The print does not sit on top, so you get a smooth look. This finish works well for gift bags or fashion totes where you want a gentle feel. You can pick matte or glossy, depending on your taste. Many people like the matte finish because it looks classic and feels nice to touch.

DTF printing gives you a bold and vibrant finish. The print sits on top of the fabric, so colors pop and details stand out. You can choose glossy for a bright, eye-catching look. Matte is also an option if you want something more subtle. DTF prints feel a bit thicker, but they stay flexible. Your bag will look new even after many washes.

The finish you choose changes how people see your bag. A soft DTG print feels high-end and cozy. A glossy DTF print looks modern and grabs attention. Both finishes can make your bag look professional.

Here’s how finish options impact your custom bags:

- DTG gives you a softer feel. The print blends with the fabric, so your bag feels comfortable and upscale.

- DTF offers vibrant colors and strong durability. The finish stands up to wear and washing, so your bag lasts longer.

- Your choice of finish affects how your bag looks and feels. It also changes how long the print stays bright and fresh.

If you want a bag that feels gentle and looks classic, go with DTG and a matte finish. If you want bold colors and a shiny look, DTF with a glossy finish is a smart pick. You can match the finish to your brand or your personal style. When you compare dtg vs dtf printing, think about how you want your bag to look and how it will be used. The right finish helps your custom bag stand out and last.

Choosing the Right Method

When to Use DTG

You should pick DTG printing when you want your bag to show off detailed artwork or photos. DTG works best on cotton or natural canvas. If you love soft prints that blend into the fabric, this method is for you. Many artists and designers choose DTG for tote bags because it captures every line and color in their designs. You can print small batches or even just one bag without extra cost. DTG is perfect if you want to match the look and feel of custom t-shirts on your bags.

DTG printing shines when you need sharp details, smooth gradients, or lots of colors. You get a soft, professional finish that feels like part of the bag.

Choose DTG if:

- You want to print detailed artwork or photos.

- Your bags are 100% cotton or natural canvas.

- You need a soft, blended print.

- You plan to order small quantities or one-of-a-kind bags.

When to Use DTF

You should go with DTF printing if you want to print on any fabric. DTF works on cotton, polyester, nylon, canvas, and blends. If you need bright, bold colors that pop on dark or synthetic bags, DTF is the way to go. This method gives you strong, flexible prints that last through lots of use and washing. DTF also saves you time because you do not need to treat the fabric first. You can print one bag or hundreds, and every print will look sharp.

DTF printing is your best friend when you want to print on tricky fabrics or need your design to last a long time.

Pick DTF if:

- You want to print on polyester, nylon, blends, or leather.

- You need bold, vibrant colors on any fabric.

- You want prints that last and do not crack.

- You plan to order both small and large batches.

Examples

Let’s look at some real-world situations. This will help you see which method fits your project.

| Bag Type | Best Printing Method | Why It Works Well |

|---|---|---|

| Promotional Totes | DTF | Works on all fabrics, bright colors |

| Fashion Bags | DTG or DTF | DTG for soft, detailed art; DTF for bold colors on any fabric |

| Sports Bags | DTF | Handles polyester and nylon, very durable |

| Corporate Gifts | DTG or DTF | DTG for cotton, DTF for blends or synthetics |

- Artists often use DTG for tote bags with detailed artwork. The art and design community loves how DTG captures every detail.

- If you want to print a logo on a polyester sports bag, DTF will give you a strong, lasting print.

- For a big order of promotional bags in many colors and fabrics, DTF makes the job easy and cost-effective.

Checklist for Choosing Your Printing Method:

- What fabric is your bag made of?

- Do you need detailed artwork or bold, simple designs?

- How many bags do you want to print?

- Do you want a soft print or a raised, vibrant finish?

- Will your bags face heavy use or frequent washing?

If you feel unsure, talk to a professional bag manufacturer. They can help you pick the best method for your needs.

INITI Bag Services

OEM & ODM

You want your custom bag project to stand out. INITI Bag makes that easy with their OEM and ODM services. If you have a design in mind, you can work with their team to bring it to life. You get help with everything from choosing materials to picking the right printing method. OEM means you can create bags with your own brand and style. ODM lets you select from ready-made designs and add your logo or artwork. You save time and avoid stress. Their experts guide you through each step, so you get bags that match your vision.

You get full support from design to delivery. INITI Bag helps you turn ideas into real products.

Bag Types

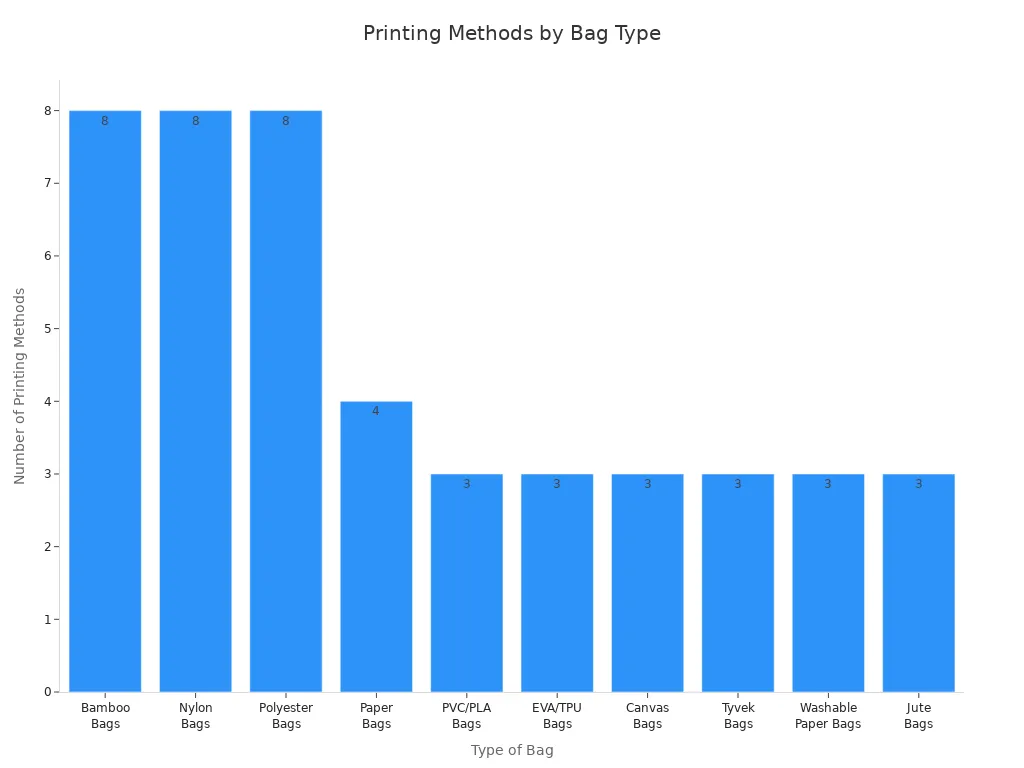

You have lots of choices when it comes to bag styles. INITI Bag offers many types, so you can find the perfect fit for your project. Whether you want eco-friendly bamboo bags, sturdy canvas totes, or sleek nylon backpacks, you have options. You can also pick paper bags for gifts, jute bags for shopping, or Tyvek bags for something unique. Each type works for different needs, like promotions, retail, or everyday use.

Here’s a quick look at the most common bag types and the printing methods you can use for each:

| Type of Bag | Printing Methods |

|---|---|

| Bamboo Bags | Silk Screen, Digital, Heat Transfer, Sublimation, Lamination, Heidelberg, Gravure, Embroidery |

| Nylon Bags | Silk Screen, Digital, Heat Transfer, Sublimation, Lamination, Heidelberg, Gravure, Embroidery |

| Polyester Bags | Silk Screen, Digital, Heat Transfer, Sublimation, Lamination, Heidelberg, Gravure, Embroidery |

| Paper Bags | Heidelberg, Lamination, Silk Screen, Digital |

| PVC/PLA Bags | Gravure, Silk Screen, Digital |

| EVA/TPU Bags | Silk Screen, Digital, Heat Transfer |

| Canvas Bags | Silk Screen, Digital, Embroidery |

| Tyvek Bags | Silk Screen, Digital, Heat Transfer |

| Washable Paper Bags | Silk Screen, Digital, Heat Transfer |

| Jute Bags | Silk Screen, Digital, Embroidery |

You can see that INITI Bag covers almost every material you might want. You get flexibility for your brand and your budget.

Printing Options

You want your logo or artwork to look sharp and last. INITI Bag gives you plenty of printing choices. You can pick silk screen printing for bold, simple designs. Digital printing works well for detailed images and lots of colors. Heat transfer printing lets you add vibrant graphics to many materials. Sublimation printing is great for polyester bags with full-color art. Lamination and Heidelberg printing offer a premium finish for paper bags. Gravure printing works for PVC and PLA bags. If you want a classic touch, embroidery adds texture and style.

You can mix and match printing methods to get the look you want. INITI Bag helps you choose the best option for your bag type and your design.

If you want your custom bags to stand out, you have the tools and support you need. INITI Bag makes it easy to create bags that match your brand and your style.

Get Started

Ready to bring your custom bag idea to life? You can start your project with INITI Bag in just a few easy steps. You do not need to be an expert. The team at INITI Bag will guide you from your first idea to the final product.

Here’s how you can get started:

- Share Your Idea

Think about what you want. Do you have a logo, a sketch, or just a style in mind? You can send your ideas, pictures, or even a rough drawing. The INITI Bag team loves to see your vision. - Pick Your Bag Type

Choose the bag that fits your needs. You can pick from totes, backpacks, drawstring bags, or something unique. If you are not sure, just ask. The team will help you find the best option. - Select Printing Options

Decide how you want your design to look. Do you want bright colors, a soft touch, or a bold finish? You can choose DTG, DTF, silk screen, or embroidery. The experts will explain what works best for your fabric and design. - Request a Quote

Tell INITI Bag how many bags you need and your deadline. You will get a clear price and timeline. No hidden fees. No surprises. - Approve Your Sample

You can see a sample before the full order. This way, you know exactly what your bags will look like. You can make changes if you want. - Place Your Order

Once you love your sample, you can place your order. The team will handle the rest. You just wait for your custom bags to arrive.

Tip: You do not have to do it alone. The INITI Bag team answers questions fast. They help you choose the right materials and printing methods.

Why Choose INITI Bag?

| Benefit | What You Get |

|---|---|

| Expert Support | Friendly help at every step |

| Fast Turnaround | Quick samples and on-time delivery |

| Quality Assurance | Careful checks for every order |

| Flexible Quantities | Small or large orders welcome |

| Global Shipping | Bags delivered to your door, anywhere |

You can start your project today. Just contact us at INITI Bag. You will get answers, ideas, and a free quote. Your custom bag project is just a click away!

Conclusion

When you choose between DTG and DTF printing for custom bags, DTF usually gives you more options and better durability. Always think about your bag’s fabric, how many you need, and the finish you want. If you feel unsure, talk to a pro for advice that fits your project. INITI Bag supports all printing methods and bag types. Ready to get started? Contact us and bring your custom bag idea to life!

FAQ

What is the main difference between DTG and DTF printing?

DTG prints ink directly onto the bag’s fabric. DTF prints your design on a film, then transfers it to the bag. DTF works on more materials and lasts longer.

Which printing method lasts longer on bags?

DTF printing usually lasts longer. The print stays bright and does not crack or peel, even after many washes. DTG prints can fade faster, especially on synthetic fabrics.

Can I use DTG or DTF on any type of bag?

You can use DTF on almost any bag, like cotton, polyester, nylon, or blends. DTG works best on 100% cotton or natural canvas. DTF is more versatile for different bag types.

Is one method better for small orders?

Both DTG and DTF work well for small orders. DTG is great for one-of-a-kind bags with detailed art. DTF is fast and flexible, even if you only need a few bags.

Which method gives brighter colors?

DTF printing gives you bold, bright colors on any fabric. DTG looks best on light cotton, but colors may look dull on dark or synthetic bags.

How do I choose the right printing method for my project?

Think about your bag’s fabric, your design, and how many bags you need. If you feel unsure, ask a professional for advice. They can help you pick the best option.